HIGH SPEED PRESSURE SEAL SOLUTIONS

Low Volume System

The CSG MM38 is a user-friendly low-volume solution for processing one-piece pressure sensitive mailers. With a speed of up to 40,000 forms per hour and the ability to process forms from 8" up to 16,5” in length and 11,8" wide, the CSG MM38 enables operators to complete daily processing jobs with ease.

Technical Info Sheet (PDF)

Call 860-574-7149 • Click email request

Mid Volume System

The CSG NET38 for a mid production environment. It has been designed using the latest in pressure sealing technology with the advantage of automatic setting and to recall 200 saved jobs. Speeds up to 43,000 forms per hour and can be linked to cutters, or even inline with high speed printers.

Technical Info Sheet (PDF)

Call 860-574-7149 • Click email request

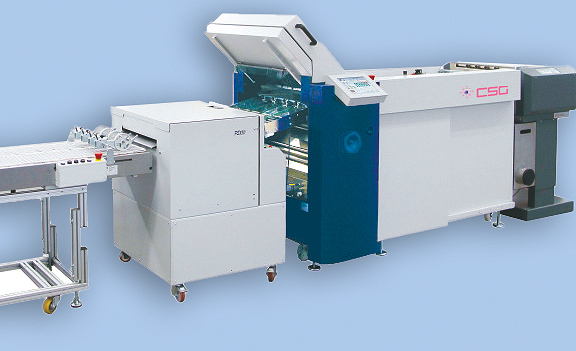

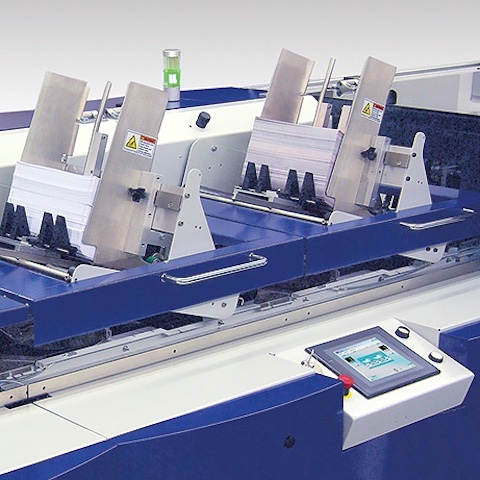

High Volume System

The CSG NET52-CONTINUOUS are designed to handle the highest volume jobs with ease and dependability. Speeds of up to 72,000 forms/h, pinfed, pinless cutter. User-friendly features: touchscreen panel, 20 standard folds pre-set , fully automated settings (feeder, register rails, fold plate stops, and much more). See Video

Technical Info Sheet (PDF)

Call 860-574-7149 • Click email request

MB BAUERLE PRODUCTS & SYSTEMS(GBR)

Folding • Inserting • Mailing

CSG Automation is authorized MB Bauerle (MB) Germay dealer and service partner (GBR) USA .

CSG focuses on part sales, service, and technical support of systems manufactured by MB including system integrations from other manufacturers with modules manufactured by MB in Germany.

CSG sells new MB systems, refurbishes MB systems and system integrations to extend their life and re-purpose them to meet new needs.

For information please call Jeff Brewer, System Sales Specialist, 860-510-9381

- Automatic and highly flexible - the new line of mailing systems autoSET B4 / autoSET B4 Hig FLEX. With feeding systems for cut sheet or continuous forms the autoSET B4 can either be used as a system machine or for the realization of complex tasks. Modular design, various kinds of feeders, can be extended to 12 insert stations. Formats from DL to B4.

- Proven conventional folding technology: multipli 35 and multimaster 38. Modular design, increased benefit through optional equipment.

- Prestige foldNET fully automated Folding Systems expandable for integration. Interfaces for online connection with digital printing systems: Cut-sheet printer and continuous forms systems.

High-Performance Inserting & Mailing Systems

autoSET B4 / autoSET B4 HighFLEX

The new autoSET B4 line of inserting systems features a high degree of variability combined with top-level operator convenience. The inserting system handles all formats from DL to B4. With feeding systems for cut sheet or continuous forms, the autoSET B4 can either be used as a system machine or for the realization of complex tasks.

Incredibly versatile and at the same time really fast: autoSET B4 HighFLEX! This High-Performance Inserting & Mailing System combines high speed with unprecedented flexibility. The system has been designed for those usages where maximum outputs with minimum set-up times are required. The combination with the extremely wide range of applications and formats makes the system the unique multi-format machine on the market.

Video autoSET-B4 • Video autoSET-B4-highflex • Technical Info Sheet (PDF)

Multi-Flexible Inline System - Creasing and folding in one pass

MB folding systems in combination with Bacciottini Pit Stop creasing and perforating machines

A typical problem when folding digital prints or other delicate materials is the cracking of the toner layer along the fold line. Creasing along the fold line can considerably reduce or even avoid the cracking of the printing ink. With the creasing technology of the Pit Stop models, the material is gently compressed because stretching of the paper fibres is avoided.

The Multi-Flexible Inline System allows efficient inline processing when products have to be creased before folding. MB folding systems of the model series prestigeFOLD NET and multimaster can be easily combined with the Pit Stop creasing machines.

Technical Info Sheet (PDF)

Conventional Folding Technology - in two basic versions

From simple parallel folds to professional cross folds

Commercial success is the result of smooth processes – this applies in particular to print processing. The folding machine multimaster 38 stands for this principle, since it is a professional system that meets your needs – and not the other way round. Its modular design and the comprehensive range of attachments turn each multimaster 38 into a custom-made folding machine. The machine concept comprises two different basic versions.

The roller diameter of 40 mm makes the multimaster 38-40 the ideal all-round machine for all common folding jobs. The multimaster 38-30 with its roller diameter of 30 mm is especially suitable for handling small folds and light stock.

Technical Info Sheet (PDF)

BACCIOTTINI • PITSTOP PRODUCTS & SYSTEMS

CSG Automation is an authorized Bacciottini (PitStop) dealer and service partner in the USA.

CSG Automation focuses on part sales, service, and technical support of all PITSTOP models manufactured by BACCIOTTINI - including system integrations with modules like "Multi Flexible Inline System" manufactured by MB BAUERLE.

CSG sells new PitStop systems, refurbishes PitStop Inline systems and system integrations to extend their life and re-purpose them to meet new needs.

For information please call Jeff Brewer, System Sales Specialist, 860-510-9381

CSG services & parts for Bacciottini:

- PITSTOP Creasing, Cutting and Perforating Systems

- Perforating & Creasing Systems for Print On Demand

- Creasing Machines for Highest Performance

- Pulsed Perforation Machines

- Multi Flexible Inline Creasing System

Perforating & Creasing Systems for Print On Demand

PIT STOP DGLINE 8000 TOUCH

Automatic perforating/creasing machine with a low pile feeder. The new DG Line is ideal for the companies who offer “print on demand” and who expect high quality products from digitally printed stock with fast and simple operation.

The format is adapted to digital and also book covers (books on demand) standard 50 x 70 cm (19,6" x 27,5"), option with extension 50 x 85 cm (19,6" x 33,4"), and can crease up to 400 gsm. It is also possible on the DG Line to attach a standard perforating kit (optional extra) which can be programmed directly from the display.

Equipped with user friendly seven inch colour touch screen reaches speeds of 8,000 sheets per hour (A4 with 1 crease).

Dedicated to the print on demand and digital printing has great accuracy.

Technical Info Sheet (PDF)

SERVICE • REPAIRS & ORIGINAL PARTS

Best results from CSG Automation with manufacturers’ original parts

| Part number | Description | Category | Price |

|---|---|---|---|

| 427-16430 | ROLLER, FEED GBR 420-438 |

GBR Parts | $ 35,00 |

| 427-22221-000 | PULLEY ASM, FEEDER GBR 420-438 |

GBR Parts | $ 190,62 |

| 427-25212-600 | SHAFT CLUTCH, HARDENED GBR 420-438 |

GBR Parts | $ 80,00 |

| 427-30080-500CPR | BRUSHED DC MOTOR DRIVE GBR 438 V3, FEEDER CUST. PRODUCT FOR REPAIR |

GBR Parts | $ 475,00 |

| 427-30307-600 | TRACTOR BELT, YELLOW GBR 420-438 |

GBR Parts | $ 44,50 |

| 72-18014-007 | O-RING, ACCELERATOR PB FLOWMASTER 18014-007 |

Pitney Bowes | $ 7,00 |

| 72-90000-035 | TIMING BELT DOUBLE, 270 L 075 PB FLOWMASTER |

Pitney Bowes | $ 18,10 |

CSG Automation manufacturer authorized and reliable repair service

With original manufacturer authorized repair service from CSG, your systems are optimized for consistent performance and reliability.

SG offers a wide range of fully integrated solutions comprising many high-quality components and modules. Over time they may need to be replaced or repaired. To ensure optimum performance and durability we provide precise rapid assistance and support with consumables, spare parts and repair needs.

Arrange for a consultation by contacting us

Phone 860-574-7149 • Click to email service

Get the best results from CSG Automation with OEM parts, we offer a wide variety of parts for mailing equipment that we guarantee will meet your expectations.

The parts we supply or produce are made with the precision to meet or exceed the OEM's requirements from manufacturers like GBR Systems, MB Bauerle, Bell and Howell, Pitney Bowes, Bacciottini (PitStop), Tecnau, Pressure Sealers (Paragon).

GBR Parts, Pitney Bowes Parts, Bell and Howell Parts. The most common spare parts are always in stock to guarantee a fast delivery. See the parts excerpt in the table.

Arrange for a consultation by contacting us

Phone 860-574-7149 • Click to email parts

ABOUT US

- 36-D Industrial Park Road,

Niantic, CT, 06357 - Inserters, Feeders

- Folders, Cutters

- Creasers, Pressure Sealers

SALES

We understand your business needs are unique, so our solutions are designed to be as flexible and agile as possible to help your business gain a competitive edge. Team up with CSG today and discover how your production can benefit:

For information please call Jeff Brewer, System Sales Specialist, 860-510-9381,

Click to email sales

JOBS

Business Administrator

CSG Automation LLC seeks a Business Administrator to oversee and analyze financial operations; maintain up-to-date records and reports; oversee payroll functions; supervise staff members and delegate responsibilities; plan and administer budget plan; provide administrative support to finance team. Supervise accountants and engineers.

Requirements: Bachelor’s degree in finance, accounting or related and 12 months of experience in Finance or Accounting.

Resumes Attn:

V. Abreu, 77 Somersett Drive, Mystic, CT, 06355.

Posted on 02/20/2023